THE NEW GENERATION OF PP-RCT PIPING LINES

We by ALMATEHRM use for our piping systems the most advanced and up-to-date raw materials / granulates on the market.

Plastic pipes made from Polypropylene Random Copolymer (PP-R Type 3) were introduced more than 20 years ago. Since then, they have been used mainly for hot and cold water pipe systems and have significantly contributed to the growth and acceptance of plastic pipes for plumbing and heating systems. Over the time, system components have been gradually improved, more data and testing has been done on the material. This led to the development of PP-RCT (New Class of PP-R material – Type 4).

Systems made of PP-RCT material can be operated at higher stresses at elevated temperatures. Pressure tests in accordance with ISO 9080 on pipes manufactured from PP-RCT materials demonstrate a 50 year strength at 70°C of 5 MPa, compared to the 3.2 MPa for standard PP-R materials. Offering more than a 50% improvement in long-term strength, the new PP-RCT material enables designers to select thinner walled pipes and in some situations also smaller diameter pipes can be used. This results in higher pipe hydraulic capacity or the possibility to apply higher pressure than with standard PP-R.

The unique performance of PP-RCT granulates is based on three building blocks. On the one hand a multiple-reactor technology is applied to tailor the molecular structure with respect to the molecular weight, molecular weight distribution, co monomer content and distribution. On the other hand PP-RCT possesses a unique morphology using a special “ß-nucleation” process. In comparison to standard PP-R, which displays only alpha (α) crystals, the crystal structure of PP-RCT consists to a high degree of ß-crystals and to a minor extent of a-crystals. The special ß-nucleating leads to a fine crystal structure and a homogeneous crystallite size distribution, attributes that positively affect the mechanical characteristics of a material. A state-of-the-art stabilization and additive package constitute the third building block. This specially designed additive package is based on Boreali’s long-term experience in the field of polyolefin’s for hot water applications and provides superior long-term heat resistance as well as excellent resistance to leaching.

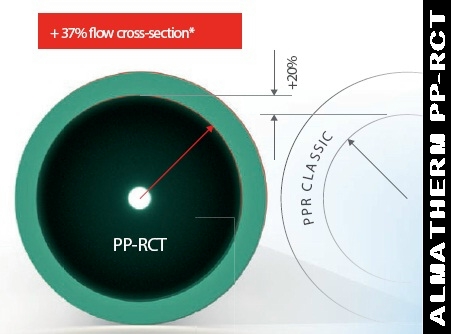

ALMATHERM PP-RCT pipes utilizes superb properties of the PP-RCT material in smooth wall and multi-layer pipes. Compared to the PPR pipes, the PP-RCT material enables to achieve the same or better pressure and thermal endurance with lesser pipe wall thickness.

MAIN ADVANTAGES:

1. A flow cross-section is higher by 37 % compared to PPR pipes.

2. A proven way of connecting by polyfusion welding as in the case of PPR.

3. A higher range of working temperatures for a given application “HOT” or “COOL”.

4. A third as high thermal expansivity as in the case of PPR pipes (in the case of PP-RCT FASER and STABI).

5. A lifespan of more than 50 years

ALMATHERM PP-RCT pipes comes now in 5 modifications according to the application:

ALMATHERM PP-RCT HOT. Suitable for hot water distributions. For applications between 20°C/2,0MPa - 70°C/1,0MPa

ALMATHERM PP-RCT FASER HOT with glass fibers. Suitable for hot water and heating distributions. For applications between 20°C/2,0MPa-70°C/1,0MPa with maximum diameter of D=125 and 20°C/1,6MPa-70°C/0,8MPa for diameters D=160 and higher. Coefficient of thermal expansion t=0,05mm/m.°C

ALMATHERM PP-RCT STABI with a compact Aluminium-oxygen barrier. Suitable for high-temperature heating distributions. For applications up to 70°C/1,0MPa - 90°C/0,8MPa Coefficient of thermal expansion t=0,05mm/m.°C

ALMATHERM PP-RCT UNI A universal piping for water and air distributions. For applications up to 20°C/1,6MPa-60°C/0,8MPa

ALMATHERM PP-RCT FASER COOL with glass fibers. Suitable for cold water and air distributions. 20°C/1,6 MPa-70°C/0,8MPa with maximum diameter of D=125 and 20°C/1,0MPa-70°C/0,5MPa for diameters D=160 and higher. Coefficient of thermal expansion t=0,05 mm/m.°C

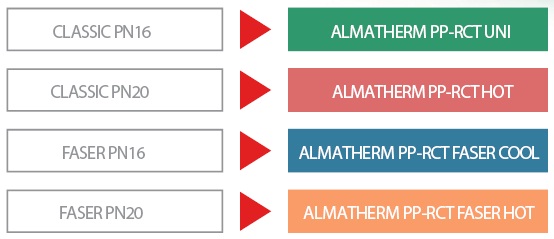

With consideration of the superior material advantages PP-RCT granulates provide, ALMATHERM will adjust it’s products program to use more and more this modified material in the production of it’s different piping systems. An overview of the modifications of the CLASSICAL PPR piping lines and the new PP-RCT piping lines alternatives is as follows:

>Home< >About Us< >Products (PPR Pipes // PERT Hot Pipes // PEXc Hot Pipes // PEXc Pipes // PERT-AL Pipes // PEXc-AL Pipes // HDPE Pipes // PPR Fittings // PPR Threaded Fittings // PPR Valves // Accessories // Welding Tools)< >Library< >Contact<