|

|

16) NEW PE-Xc Pipes System: ALMATHERM PE-Xc Material: PE-Xc Standard: EN ISO 15875, DIN 4726 Details: single-layer PE-Xc pipe without oxygen barrier used mainly in the drinking water installations. |

| Dimension | Unit | Large package | Small package | Weight [kg/pcs] |

Volume [dm3/pcs] |

Catalog number | D [mm] | s [mm] | I [mm] |

|---|---|---|---|---|---|---|---|---|---|

| 12 x 1,8 | m | 200 | foil | 0,090 | 0,60 | AA131012200 | 12 | 1,8 | 200 |

| 16 x 2,2 | m | 200 | foil | 0,090 | 0,60 | AA131016200 | 16 | 2,2 | 200 |

| 20 x 2,8 | m | 200 | foil | 0,100 | 0,60 | AA131020200 | 20 | 2,8 | 200 |

| 25 x 3,5 | m | 200 | foil | 0,100 | 0,60 | AA131025200 | 25 | 3,5 | 200 |

| 32 x 4,4 | m | 200 | foil | 0,110 | 0,60 | AA131032200 | 32 | 4,4 | 200 |

| 40 x 5,5 | m | 200 | foil | 0,110 | 0,60 | AA131040200 | 40 | 5,5 | 200 |

Demands on the heating pipe:

The single-layer PE-Xc pipe without oxygen barrier is used primarily in the drinking water installation (in other countries also in heating)

The PE-Xc provides the following benefits:

* very good long-term resistance during the internal pressure test

* good thermal ageing stability, thus no damages caused by thermal ageing when used in ccordance with the regulations

* stress cracking resistance

* good resistance to chemical solvents, i.e. also resistant to heating water additives such as inhibitors

* installation at low temperatures possible without heat treatment

* laying with narrow bending radii

* corrosion resistance

* smooth pipe walls, i.e. minimal pressure loss and no incrustations

* good rapid crack propagation resistance and abrasion resistance

* impact resistance at low temperatures

The ALMATHERM electron beam cross-linked PE-Xc pipe has all these properties. The requirements set forth in EN ISO 15875 for PE-Xc pipes are met and even surpassed.

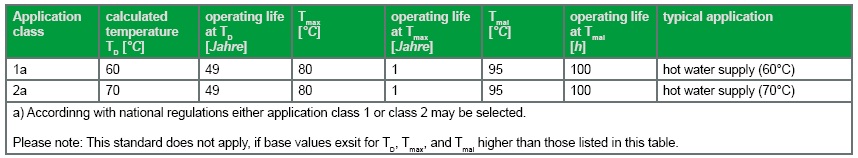

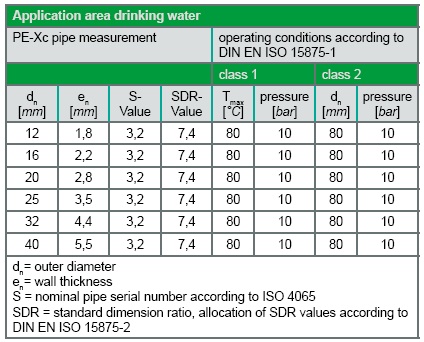

Classification of operating conditions according to EN ISO 15875-1:

Standard PE-Xc pipes:

Raw Material:

The basic material consists of high density polyethylene types of a high molecular weight supplied by renowned raw material producers. Special additives prevent thermal degradation and the influence of metal ions (e.g. of brass fittings).

Pipe Production:

The pipes are extruded in a pipe extrusion process on state-of-the-art manufacturing plants, which have been optimized for the processing of polyethylene of high molecular weight.

Corsslinking:

Crosslinking, i.e. the linking of the polyethylene molecules to a macromolecule with a spatial network is continuously done after extrusion by fast high-energy electrons on Europe's most modern and efficient electron accelerators. During this process no radioactive beams are emitted. Thus, the electron beam cross-linked pipe is no source of radiation!

Due to the crosslinking the known dropping of the internal pressure resistance - particularly when higher temperatures are concerned - is avoided. In addition, the pipe is insensitive to stress cracking and the influence of chemicals ensured by the corsslinking procedure.

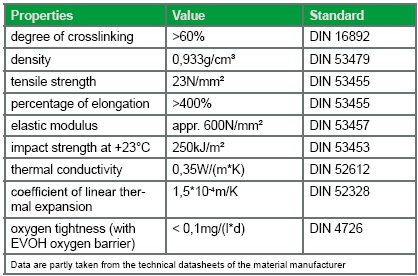

Technical properties of the ALMATHERM PE-Xc pipes:

Quality assurance by internal control:

During production the PE-Xc pipe of ALMATHERM has to undergo strict controls according to the relevant product standards such as DIN 16892/16893 resp. DIN EN ISO 15875.

Among other investigations, the following tests are made:

* preprocessing control of the raw material charges

* dimensional continuity and accuracy of the pipes

* mechanical-technological tests according to standard, eg internal pressure test

Quality assurance by external control:

The most important characteristics are constantly tested within the scope of supervision contracts.

>Home< >About Us< >Products (PPR Pipes // PERT Hot Pipes // PEXc Hot Pipes // PEXc Pipes // PERT-AL Pipes // PEXc-AL Pipes // HDPE Pipes // PPR Fittings // PPR Threaded Fittings // PPR Valves // Accessories // Welding Tools)< >Library< >Contact<