|

|

17) NEW PE-RT / AL Pipes System: ALMATHERM PE-RT / AL Material: PE-RT / AL / PE-RT Standard: EN ISO 15874, DIN 8077, DIN 8078 Details: Five-layer, polyethylene pipe PE-RT II with an longitudinally welded aluminium layer. Increased heat resistance (acc. to EN ISO 22391). Oexygen barrier of aluminium according to DIN 4726, Tmax 95°C.

|

| Dimension | Unit | Large package |

Small package |

Weight [kg/pcs] |

Volume [dm3/pcs] |

Catalog number | D [mm] | s [mm] | I [mm] |

|---|---|---|---|---|---|---|---|---|---|

| 16 x 2,0 | m | 200 | cardboard | 0,105 | 0,60 | AA130016200 | 16 | 2,0 | 200 |

| 16 x 2,0 | m | 400 | foil | 0,105 | 0,60 | AA130016400 | 16 | 2,0 | 400 |

| 18 x 2,0 | m | 200 | cardboard | 0,123 | 0,60 | AA130018200 | 18 | 2,0 | 200 |

| 20 x 2,0 | m | 200 | cardboard | 0,148 | 0,60 | AA130020200 | 20 | 2,0 | 200 |

Demands on the Pipe:

The most important component of a heating system, or a potable water installation, is the pipe. The PE-RT / AL / PE-RT multilayer pipe provides the following benefits:

* minimized linear expansion

* dimensionally stable after installation and operation

* pressure and temperature-stable

* high reliability of assembly under site conditions

* no harassment by flow noise at constant flow rates

* impermeable to oxygen (according to DIN 4726)

* high resistance to aggressive water or additives

* resistant to corrosion and incrustation due to smooth inner surfaces

* maximum safety due to butt-laser-welded seam

* optimum bonding of the layers by polymeric adhesive layer

These properties fulfills the ALMATHERM PE-RT / Al / PE-RT - pipe.

The requirements of EN ISO 21003-2 for multilayer pipes and DIN 4726 for heating pipes are met and exceeded in many points.

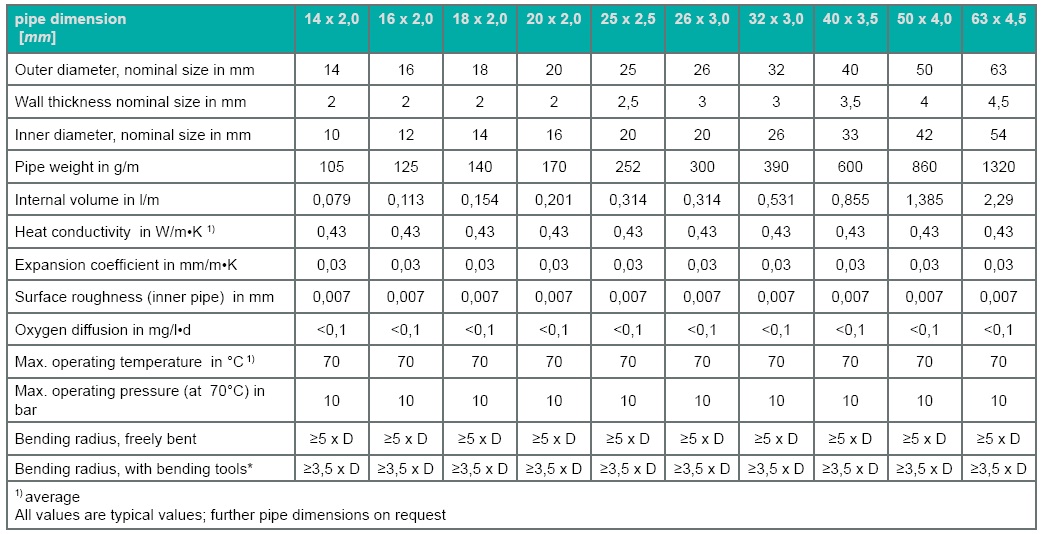

Specifications of PE-RT/AL/PE-RT pipes (informative):

Raw Material:

The pipe consists of high density polyethylene of raised temperature resistance (PE-RT type II) with a butt laser TIG welded aluminium sheathing and a top coat of polyethylene (PE-RT type II).

The basic pipe is made of a special polyethylene quality which has excellent compressive strength and ageing properties due to copolymerization.

Examinations according to ISO 9080 carried out through independent institutes have attested the conformity of the basic material to product standard and have proven this material to be a PE-RT (polyethylene of raised temperature resistance).

Owing to the minimised creep tendency of the basic material this system is particularly suitable for the use with pressure fitting systems.

The aluminium foil used is an alloy that has been developed for this application.

The protective layer is also made of a high stability polyethylene. Due to a stabiliser packet it is protected against ageing and the influence of UV light. It is also possible to equip the protective layer with a consumer-specific finish.

Pipe Production:

The production of the pipes takes place in two steps.

* Extrusion of the polyethylene pipes on state-of-the-art extrusion units with minimal tolerances.

* Sheathing of the pipes on our laser welding units. In this process the aluminium sheet with a thickness of 200 – 800 μm is butt laser welded and durably joined to the basic pipe by means of an adhesive layer. Then, the pipe is equipped with a cover sheet of polyethylene which serves as a protection against corrosion and gives the pipe a customer-specific finish.

Quality assurance by internal control:

During production the PE-RT/AL/PE-RT pipe of ALMATHERM has to undergo strict controls according to the relevant product standards such as DIN EN ISO 21003-2.

Among other investigations, the following tests are made:

* preprocessing control of the raw material charges

* dimensional continuity and accuracy of the pipes

* mechanical-technological tests according to standard, eg. internal pressure test

Quality assurance by external control:

The most important characteristics are constantly tested within the scope of supervision contracts. Depending on the country and the type of pipe, the pipes are supervised.

>Home< >About Us< >Products (PPR Pipes // PERT Hot Pipes // PEXc Hot Pipes // PEXc Pipes // PERT-AL Pipes // PEXc-AL Pipes // HDPE Pipes // PPR Fittings // PPR Threaded Fittings // PPR Valves // Accessories // Welding Tools)< >Library< >Contact<