ALMATHERM pipes and fittings are produced from high quality Polypropylene Random Copolymer (PP-R) Type 3 as raw material having low melt flow rate, high molecular weight and good flexibility. Its physical chemical properties make ALMATHERM a versatile piping system in a wide range of applications in different industries.

This raw material is recommended for the production of pressure pipes including potable water transfer lines, hot and cold water transfer lines, floor heating and also for chemical industry applications. Good long term pressure resistance and easy processing and installation technique give cold and hot water systems made of PP-R pipes an advantage as alternative to the traditional systems. Its advantages over other PP type 1 or 2 and other thermoplastic pipes in the portable water industries are its high impact strength and resistance to high temperatures.

Polypropylene Copolymer type 3 corresponds to German DIN standards:

a- DIN 8077 Dec. 1997 PP Pipe Dimensions

b- DIN 8078 April 1996 PP Pipes General Quality Requirements and Testing.

What is Polypropylene Random Copolymer (PP-R)?

The main factor that determines the life and performance of all piping systems is the material it’s manufactured from. Most materials used now for the different piping systems cannot be seen as the optimal choice for water transportation. The piping material should not affect water quality being transported, nor should the water it self damage the pipe. In addition, the material used should be of long life to secure a functional piping system that could last as long as the building objects them self would. A faulty piping system could reduce the life of other elements in the building.

• Material choice affects both effectiveness and life span of a piping system.

• An optimal piping material would not take on or be affected by water.

• An optimal piping material should last as long as the building used in.

We by ALMATHERM use PP-R (polypropylene-random) to manufacture our pipes and fittings. This material assures a piping system that will show high durability, good weldability, homogeneous joints, low tendency to incrustrations and fast and easy installation. Polypropylene is a durable, long-lasting material that does not interact with water making it an optimal alternative that can be used for pure water systems. In addition, polypropylene can only be affected by a limited number of chemicals so that it can be used in acid waste systems. The physical and chemical advantages of the polypropylene-random material make it the optimal choice for potable water as well as for heating and cooling distribution piping systems.

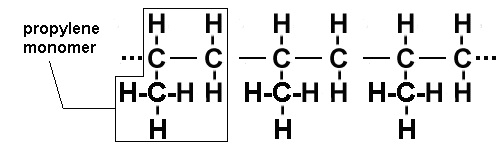

Polypropylene consists of chains of hydrocarbons in such a plain and simple chemistry that gives the material the characteristic of being tough and long lasting.

Using Short Chains in the material production process makes the polypropylene flexible. Using Long Chains in the production makes the polypropylene rigid. But in the polypropylene-random material production process a mixture of long chains and short chains is used to create a material that is both rigid and flexible. The flexibility helps protect pipes from external damage such as freezing and impact. In addition, it allows the pipe to absorb stress that might damage other systems (including expansion stresses). The rigidity helps improve the performance and appearance of the system and secures a clean branch system preferred by most building owners.

Short Chains Long Chains

Random Chains

ALMATHERM uses only the highest quality polypropylene resin from BOREALIS (one of the biggest German granulate manufacturers) to produce its pipes and fittings. By having the pipe and fittings come from one source, customers can be sure that they are getting consistent quality all the time.

• ALMATHERM Pipes & Fittings are made from Polypropylene Random (PP-R).

• PP-R material is suitable for use in drinking water piping systems and in acid waste piping systems.

• PP-R material is made using chains of random lengths which allows pipes to be both rigid and slightly flexible and also able to absorb most stresses, such as: freezing, impact, expansion, vibrations water hammer.

Polypropylene piping systems have many advantages when compared to other piping systems;

Compared to other rigid plastics such as PVC/UPVC/CPVC, polypropylene is much more robust. In addition Polypropylene is a non-leaching plastic meaning that no risk of the material of the pipe and/or fittings to leach in the drinking water. That makes it not only safer for the human health but will also protect the environment and our ecosystems (i.e. Polypropylene is fully recyclable). Polypropylene does not require mining to produce. It does not use hazardous or toxic chemicals in its production nor does it contain any harmful chemicals. Even the amount of electricity required to produce it is lower than other systems. A further advantage is that polypropylene is resistant to most types of chemicals – please refer to Chemicals Resistance Chart in our catalogues.

Compared to flexible plastics, such as PEX and/or PERT, the advantages fall into two main categories. The first advantage deals with the material itself. As polypropylene does no leach into drinking water thus being safer to use. It is also rigid, allowing for a conventional piping layout rather than simply drawing pipes throughout the building. Polypropylene also requires fewer fixing points.

The other main advantage is related to fitting connections and to the flow rates. Instead of being crumpled / squeezed, polypropylene pipes are heat welded to secure a consistent connection. Polypropylene pipes have a much higher flow rate than PEX/PERT pipes with their crumpled connections.

Compared to metal piping, there are many advantages also. Polypropylene pipes are more plane than metal pipes, making them almost noiseless. The polypropylene pipes have also no problems with erosion, which on the long-run can cause leaks. Since polypropylene doesn’t react with water, there is no corrosion or rusting, and no metallic taste. In many applications, polypropylene is outlasting metal pipe because of issues with water quality. Polypropylene also has a natural insulation value of about one, which reduces the amount of additional insulation needed for the different applications.

It is important to consider the expected lifespan, as well as the performance, when comparing alternative piping systems. Many piping systems use-up in a relatively short period of time requiring repairs that would end with added expenses to the objects owner. Most of the factors that might shorten the lifespan of the piping systems (such as abrasion, corrosion, scaling, hard/soft water and chemicals) do not affect polypropylene helping to extend products life for over 50 years.

• PP-R pipes have many advantages over other rigid plastics being less liable to leaks or cracking. It is also chemically purer, making it less likely to fail when exposed to other chemicals.

• Rigid pipes allow for a more efficient layout and installation. Also fused connections are more reliable than mechanical connections and have higher flow rates.

• PP-R material has many advantages over metals. Being a low friction material allows to prevent noise, abrasion, pin-hole leaks and energy loss.

• PP-R is generally non-reactive, which prevents corrosion, rusting and leaching. It has a slight insulation value, which further prevents energy loss.

• PP-R doesn’t wear out, corrode, or scale, and it isn’t damaged by most of the things that damage other materials.

There are only two nameable disadvantages of using PP-R. The first is that PP-R cannot be used in steam applications. The other issue is UV protection. If PP-R is exposed to UV radiation for an extended period of time, the pipe can become discoloured or even damaged (ALMATHERM ships the pipe in UV protected bags that can be used indefinitely to protect the pipes before installation. ALMATHERM also offers a UV-protected version of the pipes for outdoor installations).

• PP-R can be used in most applications, but cannot be used for steam.

• UV-radiation can damage the pipe, but pipes are shipped with suitable protection.

• ALMATHERM also offers a coated version of the pipe for outdoor installation.

PP-R is an ideal piping material because it does not affect and is not affected by the water that it carries. Since years, many contractors, engineers and building owners are switching to ALMATHERM’S PP-R pipes because PP-R is: long lasting, more environmentally friendly, easy to install, cost effective, rigid and durable maintenance free and able to withstand the wear and tear of accidental damage that would ruin other piping materials.

Mechanical & Thermal Properties

Polypropylene Random Co-polymer (PP-R Type 3)

![]()

ISO = International Organization for Standardization VDE = Verband Deutscher Elektroniker

The test specimens were made and the test methods selected in accordance with DIN 16774, Part 2.

Application Areas

Portable Water, Hot & Cold Water, Chemical, Irrigation

- Residential apartments, Condominiums, Public Housing

- Hotels & Resorts

- Commercial shipping centres, Office Buildings

- Industrial factories dealing with chemicals, food processing, Semi Conductors

- Hospitals

- Schools-Laboratories and chemical sewerage

Behaviour of ALMATHERM according to DIN 8078

The service life of ALMATHERM products depends on the internal hoop stress over time subject to the temperature.

Hope stress is given as follows:

Ƹ = P x (d-s)

20 x s

Where:

Ƹ = hoop sterss (N/mm² or Mpa)

P = Internal Pressure (Bar)

d = Outer diameters of pipe (mm)

s = Wall thickness of pipe (mm)

Break Strength for PP-R Pipes according to DIN 8078:

![]()

The Comparison of the Failure Time (h) & the Design Stress (MPa) for the PP pressure pipes at 20°C and 60°C:

![]()

Permissible Operating Pressure Projected Service Life

The table shown provides more detailed information with regards to the permissible pressure of various pipe pressure ratings at various temperatures. These values derived from the hoop stress chart and formula.

Under normal working pressures and conditions, the average service life of ALMATHERM pipes is projected to be 50 years or more.

Example:

A PN10, cold water pipe, transporting water at a temperature of 30°C can last for more than 50 years under normal conditions with an operating pressure of 11,1 Bars or 161 PSI.

A PN20, hot water pipe, transporting water at a temperature of 70°C can last for more than 50 years under normal conditions with an operating pressure of 8,5 Bars or 123 PSI.

![]()

SDR = Standard Dimension Ratio (Diameter/Wall Thickness Ratio) SDR = d/s (s = pipes series index from ISO 4065)

Hygiene & Health Concerns

ALMATHERM Products are manufactured with health concerns in mind.

* Connection of pipes does not require additives such as cement solvent of fluxes of solder.

To ensure the safety of ALMATHERM pipes and fittings for usage relating to human contact and consumption with portable water, the following are strictly adhered to:

- DIN 1988 Part 2 D

Drinking Water Supply Systems Materials Components Appliance Design and Installation.

- KTW-Recommendations

Federal health office, Germany

- DVGW

Test Certificate based on KTW recommendations for Materials in Contact with Drinking Water.

Hygiene & Health Concerns

ALMATHERM Products are manufactured with health concerns in mind.

* Connection of pipes does not require additives such as cement solvent of fluxes of solder.

To ensure the safety of ALMATHERM pipes and fittings for usage relating to human contact and consumption with portable water, the following are strictly adhered to:

- DIN 1988 Part 2 D

Drinking Water Supply Systems Materials Components Appliance Design and Installation.

- KTW-Recommendations

Federal health office, Germany

- DVGW

Test Certificate based on KTW recommendations for Materials in Contact with Drinking Water.

UV Resistance

ALMATHERM products are produced with UV stabilisers. However, like all other piping systems including metals, pipe work should not be left exposed under direct sunlight without insulating or protection from direct sunlight or UV radiation.

Fire Classification

ALMATHERM pipes and fittings comply and are classified under the requirements of the fire classification, B2 (Normally inflammable) according to DIN 4102. In case of a fire outbreak of temperature 800°C under ideal conditions with sufficient oxygen only carbon dioxide and water vapour are produced as the raw material of Polypropylene random co-polymer is a hydrocarbon chain Toxic fumes or dioxin will not be emitted.

Sound Insulation

Compared to metallic pipes, an ALMATHERM product does not need further insulation to decrease the decibel level when water flows at relatively high speeds. The reason is simply that metals transmit noises quicker and louder, whereas, plastics dampen to noises. Hence whistling and noises resulting from water hammer effect are largely reduced to non-existence.

Advantages of Using ALMATHERM

From the above properties of ALMATHERM system and application areas, compared to other conventional metal or plastic piping systems ALMATHERM has the following advantages which makes it THE SYSTEM OF THE FUTURE.

- Not Detrimental to Human Health

- Rust and Corrosion Free

- Rupture Free

- No Scaling

- High Resistance to Acids and Chlorides

- Noise free at high flow rates

- High pressure tolerances and rating

- Insulation is not necessary for interior applications

- Light weight

- Speed and Ease of fusion technology

- Extensive savings in time and labour

- PN20 system bursting pressure 106 Bars

- PN10 system bursting pressure 33 Bars

>Home< >About Us< >Products (PPR Pipes // PERT Hot Pipes // PEXc Hot Pipes // PEXc Pipes // PERT-AL Pipes // PEXc-AL Pipes // HDPE Pipes // PPR Fittings // PPR Threaded Fittings // PPR Valves // Accessories // Welding Tools)< >Library< >Contact<